History of Overcurrent Protection

Overcurrent protection has been an important part of the electrical industry since the early days of electrical systems. As early as the 1800s, electrical engineers recognized the need to protect electrical systems from faults and overloads. This led to the development of early forms of overcurrent protection devices, including fuses and circuit breakers.

Fuses were one of the earliest forms of overcurrent protection devices. They consist of a metal wire or filament that melts when exposed to excessive current, breaking the circuit and preventing further flow of current. The first patent for a fuse was filed in 1885 by Thomas Edison, who was seeking a way to protect his new electrical power distribution system. Learn more

Circuit breakers were another early form of overcurrent protection devices. They were developed in the early 1900s and were designed to replace fuses in certain applications. Circuit breakers use an electromagnet to trip the circuit when excessive current is detected, similar to the operation of a modern circuit breaker.

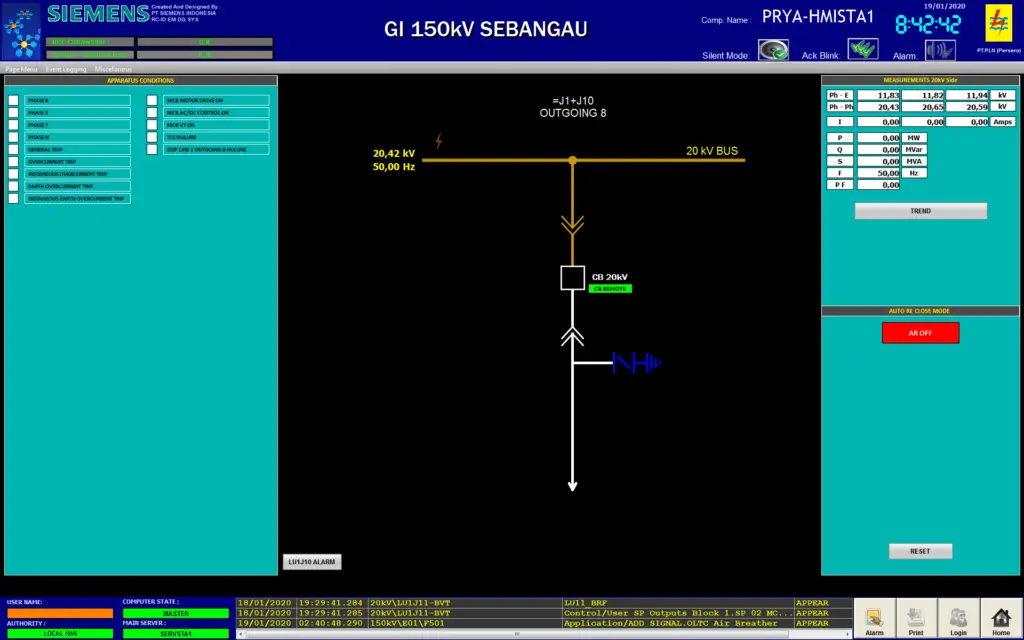

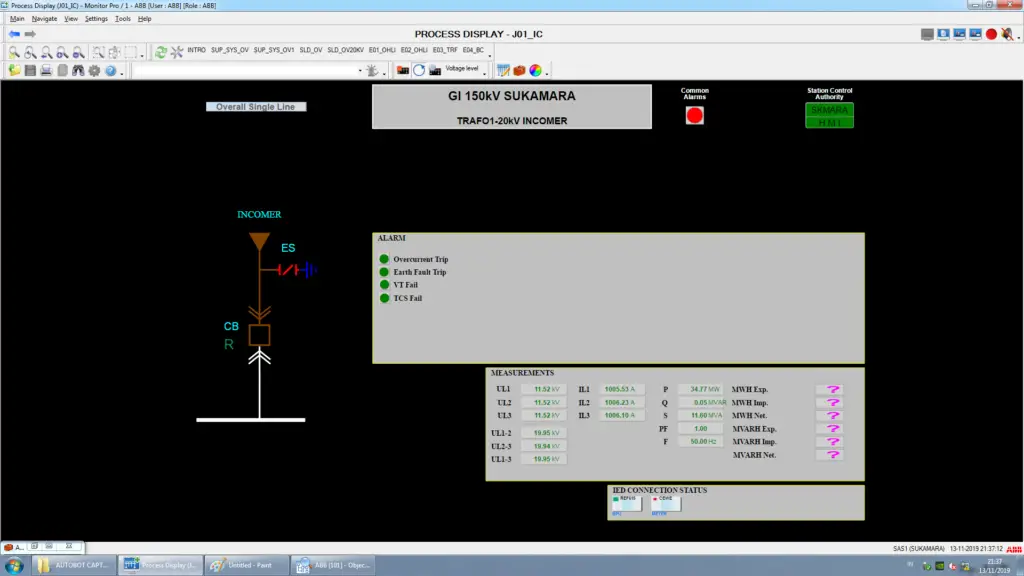

Enhancing Efficiency and Safety: The Power of HMI Software

Over the years, advances in technology and the increasing complexity of electrical systems led to the development of more advanced forms of overcurrent protection devices. In the 1920s and 1930s, protective relays were introduced. These devices used electromagnetic or thermal sensors to detect faults and trip circuit breakers when necessary.

The development of solid-state electronics in the 1960s and 1970s led to the introduction of static relays. These devices used electronic components to detect faults and trip circuit breakers, providing faster and more accurate protection than earlier forms of overcurrent protection devices.

In the 1980s and 1990s, microprocessor-based relays were introduced. These devices used advanced algorithms and digital signal processing to analyze the electrical parameters of the system and make decisions on whether to trip the circuit breaker. This allowed for even faster and more accurate protection, as well as increased flexibility and programmability.

Today, overcurrent protection devices continue to evolve, with the development of new technologies such as digital relays and advanced communication systems. These devices are designed to provide even greater levels of protection and control over electrical systems, ensuring the safe and reliable operation of power distribution systems.

Understanding Substation Automation & IoT Concepts: A Complete guide for beginner

The history of overcurrent protection devices spans over a century and has seen the development of various forms of protection devices. From the early days of fuses and circuit breakers to modern microprocessor-based relays, overcurrent protection devices have played a critical role in the safe and reliable operation of electrical systems. The continued evolution of these devices will undoubtedly lead to even greater levels of protection and control over electrical systems in the future.

Importance of Overcurrent Protection in Power Substations

Overcurrent protection is a critical safety feature in power substations. A power substation is a facility that receives high-voltage power from the transmission lines and converts it to lower-voltage power for distribution to consumers. The substation also serves as a switching station that allows for the rerouting of power to different parts of the grid in case of a fault. In this article, we will delve deeper into overcurrent protection in power substations, its importance, and the different types of overcurrent protection devices used.

Power substations are critical components of the electrical grid. They play a crucial role in ensuring that the power supplied to consumers is safe and reliable. However, power substations are prone to faults that can cause damage to the equipment and endanger the lives of people working in the substation. Overcurrent protection is, therefore, crucial in power substations to prevent damage caused by excessive currents.

What is Remote Terminal Unit? A Basic Guide

Overcurrent protection devices are used in power substations to detect and isolate faults quickly, thus preventing further damage to the electrical system. These devices help to maintain the continuity of the power supply by ensuring that faults are quickly detected and cleared. Overcurrent protection devices are also used to protect against thermal overloads, which can cause equipment failure and prolonged power outages.

Types of Overcurrent Protection Devices Used in Power Substations

Power substations use a variety of overcurrent protection devices to protect against faults and overloads. The following are the most commonly used overcurrent protection devices in power substations.

Circuit Breakers

Circuit breakers are the most commonly used overcurrent protection devices in power substations. They are designed to interrupt the flow of current when it exceeds a safe limit. Circuit breakers are available in different types, including air, oil, vacuum, and SF6 circuit breakers. Air circuit breakers are the most common type of circuit breaker used in power substations, while SF6 circuit breakers are used in high-voltage applications.

Circuit breakers are used to protect against overloads, short circuits, and faults in power substations. They are designed to trip when the current exceeds a certain level, thus interrupting the flow of electricity. The tripping mechanism of a circuit breaker can be either thermal or magnetic. A thermal trip mechanism uses a bimetallic strip that bends when it gets hot due to excessive current, while a magnetic trip mechanism uses a solenoid to trip the circuit breaker when the current exceeds a predetermined level.

Fuses

Fuses are another type of overcurrent protection device used in power substations. They are designed to interrupt the flow of current when it exceeds a safe limit. Fuses are one-time-use devices that must be replaced after they have been triggered. Fuses are available in different types, including cartridge fuses, expulsion fuses, and current-limiting fuses.

Cartridge fuses are the most commonly used type of fuse in power substations. They are available in different sizes and current ratings and are designed to protect against overloads and short circuits. Expulsion fuses are used in high-voltage applications and are designed to extinguish the arc produced when the fuse is triggered. Current-limiting fuses are designed to limit the amount of current that flows through the circuit, thus protecting against damage caused by excessive currents.

Protective Relays

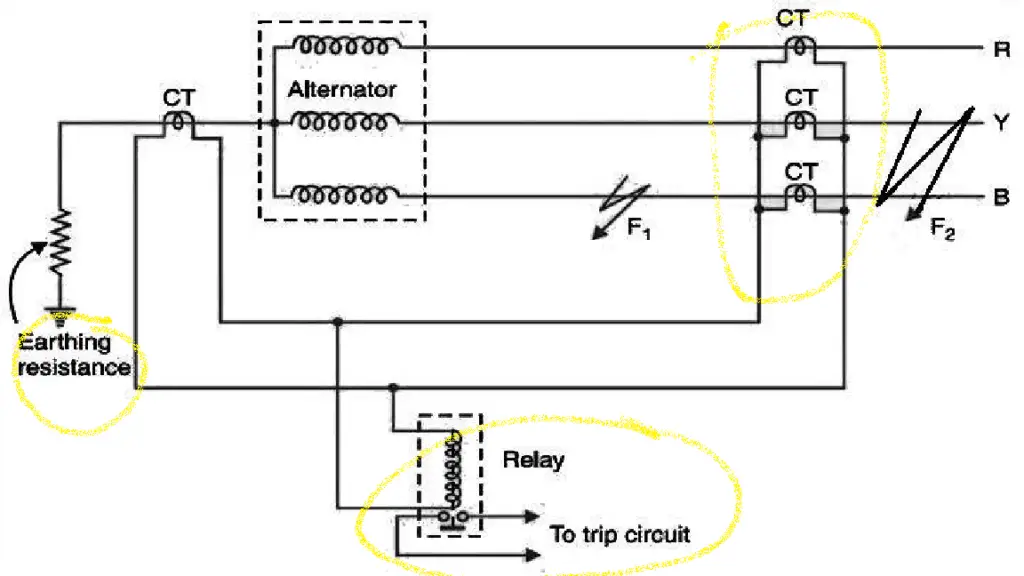

Protective relays are devices that are used to detect and isolate faults in power substations. They work by monitoring the electrical parameters of the system and tripping the circuit breaker when a fault is detected. Protective relays are available in different types, including electromechanical, static, and microprocessor-based relays.

Electromechanical relays

Electromechanical relays are the oldest type of protective relays and are still used in some power substations today. They work by using an electromagnet to trip the circuit breaker when a fault is detected. Static relays use electronic components to detect faults and trip the circuit breaker, while microprocessor-based relays use advanced algorithms to analyze the electrical parameters of the system and make decisions on whether to trip the circuit breaker.

Repair Install WinCC V7.0 SP1 Update 3 on Windows XP?

Ground Fault Protection

Ground fault protection is another critical aspect of overcurrent protection in power substations. A ground fault is a type of fault where the current flows to the ground instead of through the circuit. Ground faults can be caused by equipment failure, insulation breakdown, or other factors. Ground fault protection is important because it helps to prevent electrical shocks, equipment damage, and fires caused by ground faults.

Ground fault protection is achieved through the use of ground fault relays. These relays monitor the current flowing through the system and trip the circuit breaker when a ground fault is detected. Ground fault relays are available in different types, including zero-sequence current transformers, residual current devices, and ground fault circuit interrupters.

Maintenance of Overcurrent Protection Devices in Power Substations

Overcurrent protection devices in power substations require regular maintenance to ensure that they are functioning properly. Regular maintenance helps to prevent false trips, equipment failure, and prolonged power outages. Maintenance tasks include visual inspection, testing, cleaning, and calibration.

Visual inspection involves checking the condition of the overcurrent protection devices and their connections. Any signs of wear or damage should be addressed immediately. Testing involves checking the performance of the overcurrent protection devices to ensure that they are functioning within their specified parameters. Cleaning involves removing any dirt or debris that may affect the performance of the devices. Calibration involves adjusting the settings of the devices to ensure that they are operating within their specified ranges.

Conclusion

Overcurrent protection is a critical safety feature in power substations. It helps to prevent damage caused by excessive currents, maintain the continuity of the power supply, and protect against thermal overloads. Power substations use a variety of overcurrent protection devices, including circuit breakers, fuses, protective relays, and ground fault relays. These devices work together to ensure that the electrical system is protected from faults and overloads. Regular maintenance of these devices is necessary to ensure their proper functioning and prevent false trips, equipment failure, and prolonged power outages.

The implementation of overcurrent protection devices in power substations requires careful planning and design to ensure that the devices are installed in the most optimal locations and provide the required level of protection. In addition, the selection of the right type of overcurrent protection devices, such as circuit breakers and protective relays, should be based on the specific needs of the electrical system.

The importance of overcurrent protection in power substations cannot be overstated. It is a crucial safety feature that ensures the safe and efficient operation of electrical systems, protects against damage caused by excessive currents, and helps to prevent prolonged power outages. By implementing the right type of overcurrent protection devices and regularly maintaining them, power substations can minimize the risk of electrical faults and ensure a reliable supply of electricity to customers.

Advantages vs Disadvantages of Overcurrent Protection

Overcurrent protection is a critical aspect of electrical systems, and it offers several advantages and disadvantages. Understanding these pros and cons can help decision-makers evaluate the necessity and implementation of overcurrent protection devices in their electrical systems.

Advantages of Overcurrent Protection:

- Safety: The most significant advantage of overcurrent protection is safety. Overcurrent protection devices can prevent electrical fires, explosions, and electrocution. In the event of a fault or overload, these devices trip the circuit or isolate the faulty equipment, thus preventing damage to the electrical system and protecting the people who operate or come into contact with the system.

- System Protection: Overcurrent protection devices can prevent damage to electrical equipment and the overall electrical system. Electrical faults can cause equipment to overheat or fail, resulting in costly repairs or replacements. Overcurrent protection devices protect equipment and the electrical system by interrupting the flow of excessive current.

- Reduced Downtime: Electrical faults can cause power outages and significant downtime for businesses and individuals. Overcurrent protection devices can help reduce downtime by detecting and isolating faults quickly, enabling repairs to be made promptly, and restoring power.

- Efficiency: Overcurrent protection devices help improve the efficiency of electrical systems by preventing overloading, ensuring that electrical equipment operates within its rated limits, and reducing energy waste.

SICAM PAS Installation Mode Version

Disadvantages of Overcurrent Protection:

- False Tripping: Overcurrent protection devices can trip unnecessarily, resulting in power outages and downtime. This can occur if the device is improperly sized or if there are problems with the electrical system’s wiring or grounding.

- Cost: Overcurrent protection devices can be costly, especially when installed in large electrical systems. Moreover, high-end devices that offer more advanced features and functionality can be significantly more expensive than basic devices.

- Maintenance: Overcurrent protection devices require regular maintenance to ensure that they are functioning correctly. This can add to the overall cost of the electrical system and can require trained personnel to perform the maintenance.

- Complex Installation: The installation of overcurrent protection devices can be complicated, requiring specialized knowledge and expertise. Installing them incorrectly can cause problems with the electrical system, leading to safety risks and downtime.

In conclusion, overcurrent protection offers several advantages and disadvantages that should be weighed when considering the installation of overcurrent protection devices in electrical systems. While the benefits of safety, system protection, reduced downtime, and efficiency cannot be overstated, false tripping, cost, maintenance, and complex installation must also be considered. Understanding the pros and cons of overcurrent protection devices can help decision-makers make informed choices that balance safety, cost, and efficiency in their electrical systems.

You must be logged in to post a comment.