SIMATIC RACK PC Industrial Standard: Siemens offers a range of industrial hardware, including the SIMATIC PC series, designed for demanding industrial applications. One notable product is the SIMATIC RACK PC Industrial, known for its ruggedness and reliability. These computers are specifically designed to fit into control cabinets, making them ideal for space-constrained environments.

They come packed with advanced features, high-quality components, and extensive connectivity options. Siemens also provides software solutions like SIMATIC WinCC for visualization and process management. Overall, Siemens SIMATIC IPCs provide reliable and high-performance computing for industrial automation and control systems.

SIMATIC RACK PC Industrial Standard

When it comes to industrial hardware, having the right specifications can make a significant difference in terms of performance and reliability. Siemens, a leading provider of automation and industrial solutions, offers a range of robust and high-quality products tailored specifically for the industrial standard.

One notable product from Siemens is the SIMATIC PC, a series of industrial computers designed to meet the demanding requirements of various industrial applications. These machines are built to withstand harsh environments, featuring rugged construction and enhanced durability.

One such example is the SIMATIC RACK PC Industrial, a versatile and scalable solution that combines the power of a personal computer with the reliability and ruggedness required for industrial use. It is specifically designed to fit into control cabinets, making it ideal for space-constrained environments.

Read Also: IEC 101 vs. IEC 104: Understanding the Differences

The SIMATIC IPCs are packed with advanced features and cutting-edge technology to ensure seamless operation in industrial settings. These include powerful processors, ample memory, and extensive connectivity options. Moreover, they are built with high-quality components, ensuring long-term reliability and optimal performance.

By utilizing Siemens SIMATIC IPCs, industries can benefit from enhanced productivity, improved efficiency, and reduced downtime. These industrial-grade computers provide the necessary computing power and stability to handle demanding tasks reliably and with precision.

In addition to their robust hardware, Siemens offers comprehensive software solutions to complement their industrial PCs. This includes SIMATIC WinCC, a powerful software platform for visualization and process management, enabling efficient and intuitive control of industrial processes.

In conclusion, Siemens SIMATIC IPCs are an excellent choice for industrial applications that require reliable and high-performance computing. With their rugged construction, advanced features, and seamless integration with Siemens software solutions, they provide a solid foundation for industrial automation and control systems.

- SIMATIC IPC 547G

- SIMATIC IPC 847E

- SIMATIC IPC 1047

SIMATIC RACK PC Industrial

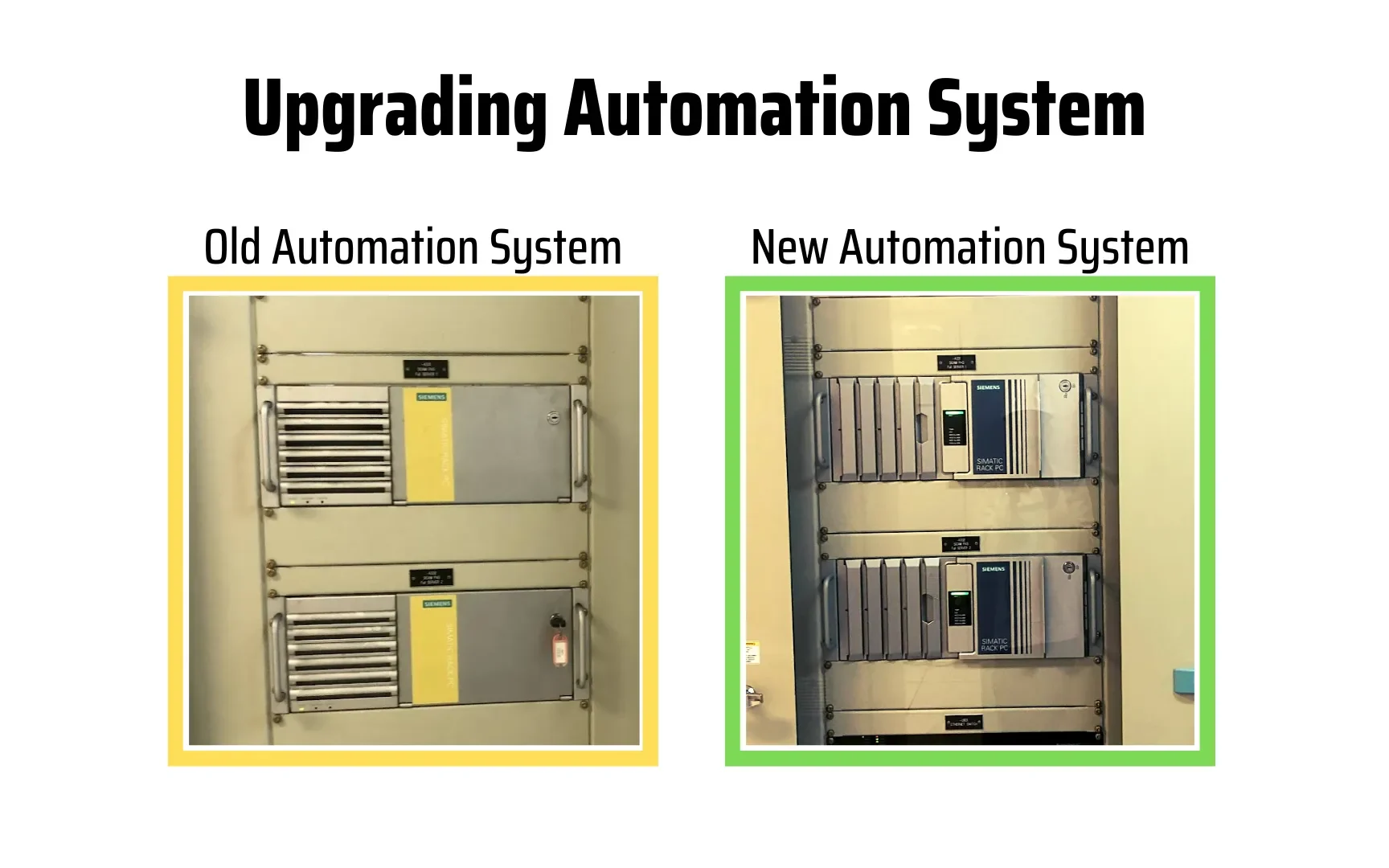

The project I was involved in was for PT. POMI East Java, where we were tasked with upgrading the Siemens Substation Automation System at the Paiton Unit 3 facility.

The original system, which had been in operation for approximately 8 years, consisted of a SIMATIC-PC. However, as technology advances rapidly, the need arose to modernize the automation system to improve its efficiency, performance, and reliability.

Our team worked diligently to develop a comprehensive plan for the upgrade. We carefully assessed the current system’s strengths and weaknesses, identifying areas for improvement. This analysis helped us determine the best course of action for the upgrade.

Once the planning phase was complete, we began implementing the upgraded Siemens Substation Automation System. This involved replacing outdated components, installing new software, and integrating state-of-the-art technology to enhance the system’s capabilities.

Read Also: Enhancing Efficiency and Safety: The Power of HMI Software

Throughout the upgrade process, our team ensured minimal disruption to the facility’s operations. We conducted thorough testing and quality assurance checks to verify the system’s functionality and compatibility with existing infrastructure. The safety and reliability of the Substation Automation System were our utmost priorities.

Upon completion of the upgrade, we witnessed a significant improvement in the performance and efficiency of the Substation Automation System. The new system allowed for more precise monitoring, control, and protection of the electrical distribution network.

PT. POMI East Java now benefits from an enhanced Siemens Substation Automation System that meets their evolving needs. The upgraded system provides them with greater flexibility, increased operational efficiency, and improved functionality.

We take great pride in successfully executing this project and contributing to the optimization of the Paiton Unit 3 facility. Our team’s expertise, dedication, and attention to detail allowed us to deliver a solution that exceeded our client’s expectations.

If you have any more questions or need further information, feel free to ask!

The most important thing to consider is the hardware specification that can be operated within almost every second while operational time.

Read Also: Cirebon Power Substation Automation Training

You must be logged in to post a comment.